Challenge: streamline operations, reduce errors and grow

St. Cloud Door Company’s business was booming, but its systems couldn’t keep up—not without breaking. They realized they need to change before things got worse so they partnered with MainSpring.

MainSpring consultants worked closely with St. Cloud to understand their business processes and engineered a solution that was both efficient and scalable. That is, when they grew, the solution could grow too. The results: streamlined operations and growth—and no more crashing Excel files or stovepipe systems!

Journey: from a spreadsheet nightmare to an automated system

For years, the company has been tracking their orders from start to finish using an antiquated Excel spreadsheet system that they have modified over and over again. It’s so complicated that staff can’t change anything in the system without it crashing. When it did break, they looked for a new solution. It’s critical because the company is based on one system used for client tracking, ordering, reporting and generating instructions for production machines. In effect, St. Cloud Owner Raj Shah called on MainSpring to devise a solution that fit with their business processes.After careful analysis, the team decided to build a custom business solution using the FileMaker 13 platform that not only delivers stability, but also improves performance, data structure and allows the system to grow. St. Cloud uses the new solution to manage the sales cycle process from beginning to end while having the ability to easily update information contained in the database—without breaking the system or bringing business to a halt.

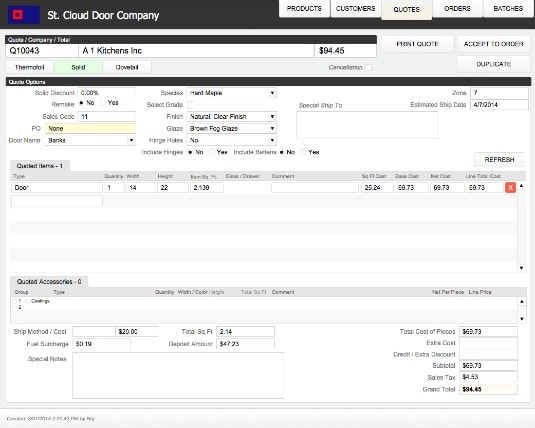

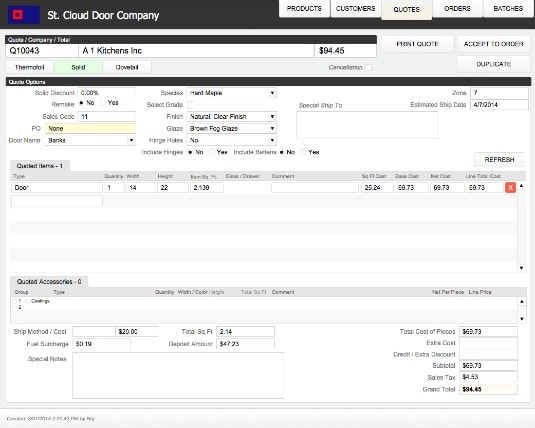

The new system also gives St. Cloud’s sales team information on demand, including detailed product information such as door styles, finishes, species and hinge types. This is a major improvement from the old system. The sales team can select products from the system and it will calculate prices in real-time and generate new quotes, reducing the sales team’s time to produce estimates and delivering quotes quicker to customers.

Once the customer approves the order, St. Cloud’s shop foreman uses the system to communicate with the production machines. The system sends electronic files with door codes and dimensions directly to the machines. There, the machines use the specifications to cut the door panels and parts used to create the finished product. Their barcode systems and streamline automation ensures quick turnaround times, fully custom, high quality doors. St. Cloud also does it green by using 100 percent water-based stain, paints and clear coatings by Sherman Williams.

Impact: speed, process improvements, happier customers

“Our products are manufactured to custom sizes with numerous variables,” Shah said. “The link between office and plant had to be perfect in order to allow proper machining of parts with no tolerance for errors. Since using the new MainSpring solution, order processing and part preparation for the plant has increased speed by 300 percent.

Our pricing structure is also very intricate and closely controlled. The organization and automation of creating costs has immensely reduced errors of pricing to our customers.

The bottom line is that the improvements to our order entries, quoting, job tracking, production planning, shipment planning, and marketing research are far beyond what we hoped for before beginning the development with MainSpring.

What’s more is that we are able to serve our customers in a more professional and timely manner.”